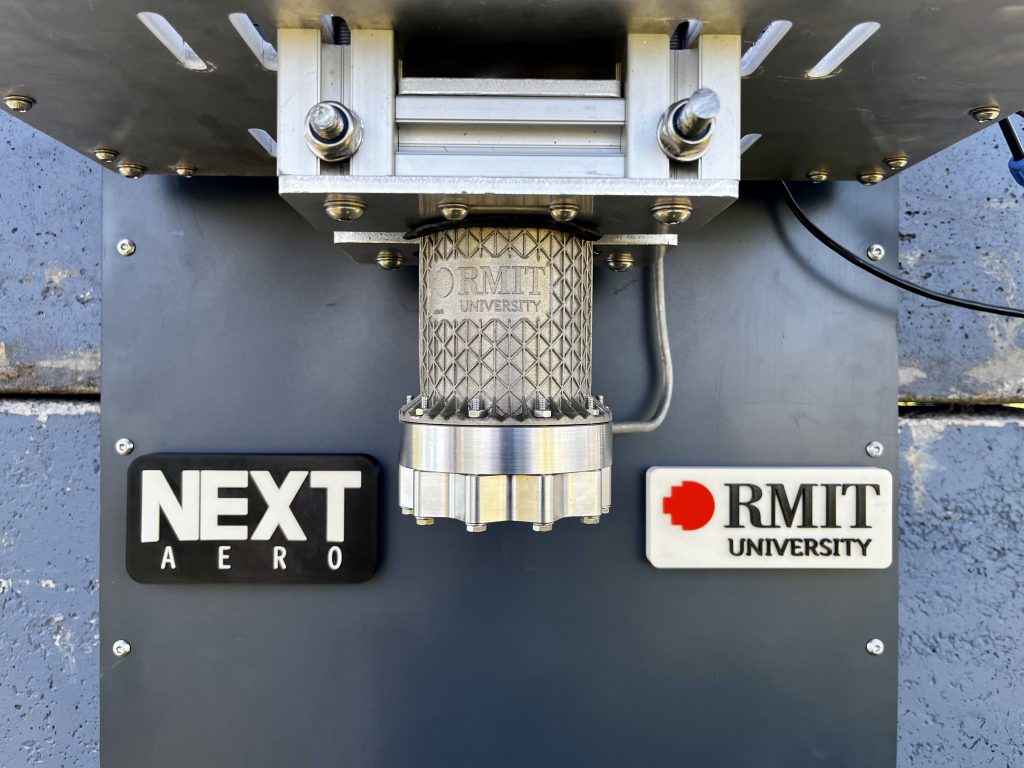

NextAero has recently worked with RMIT University to undertake testing of a metal 3D printed hybrid rocket engine. The engine was developed by RMIT University masters student, Mr. James de Salis, as part of his masters program.

The rocket engine uses a hybrid propellant combination of liquid oxidiser and a solid fuel. “The oxidiser is nitrous oxide, which has the advantage that it can make simpler to build flight vehicles without the burden of cryogenic systems for RMIT’s existing projects”, said de Sails. “The solid fuel is a special combination of parafin and a 3D printed polymer, which is one of the new elements of the design being tested”.

The testing apparatus was developed and operated by NextAero. It supplied the hybrid engine with nitrous oxide propellant as well as controlling ignition. It also provided live measurements and feedback on engine thrust, chamber pressure, propellant feed pressures and temperatures.

“Initially it was tricky to get the engine ignited” said Mr. Harry Cathcart, a Mechanical Systems Engineer at NextAero. “The high flow rate and pressure of the nitrous oxide propellant was effectively blowing out the ignition flame. However, we expected that ignition might be challenging so we added the ability to provide the engine with a trickle of propellant to get it going before more slowly introducing the main propellant flow. We managed to find a range where we could get the engine ignited and running.”

“The engine was measured to generate its designed thrust of 50kg and worked remarkably well for our initial design attempt” said de Salis. “We were also looking at how well the regenerative cooling and planned nozzle ablation were working. This testing campaign has given us a good dataset to improve our design”.